1945

advertisement from Philadelphia Toboggan Co. announcing

that post-war production of funhouse figures would

be resumed, although it is doubtful that this ever

occured.

1945

advertisement from Philadelphia Toboggan Co. announcing

that post-war production of funhouse figures would

be resumed, although it is doubtful that this ever

occured. |

|

An

examination of existing Laffing Sal figures rev-

eals paper strip layup in the torso regions which were

concealed by the clothing. But the head and hands are

much more smoothly detailed, leading to speculation

that their prod-

uction may be of another method, possibly a comp-

osition that OKC sometimes used called "Kingite", a

mixture of rosin, cornstarch and other fillers.In the

latter part of the Victor Dog prod-

uction period,

OKC

began making castings in rubber, specifically a latex

compound containing a clay filler which was poured into

plaster molds in a process similar to casting ceramics.

|

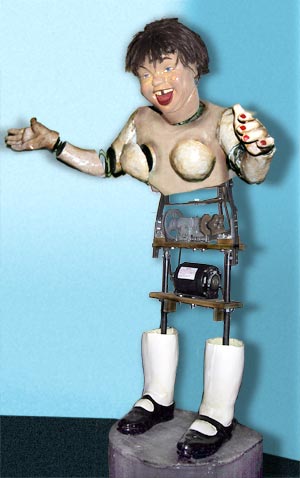

| The

major element that brought Sal to life was her unique

laughing movement.The mechanism which animated the department

store Santa figure was re-employed for Sal. There were

two basic movements: the torso moving incrementally

forward then pulling back upright, and the waving of

the arms. |

|

For

these actions two cams were used. The cams were mounted

on the single shaft of a Boston Gear 75:1 gear reduction

unit which was driven by a 1/4 hp electric motor concealed

in the hip region. A cam-pawl follower rode the underside

of each cam and linked to the upper-body torso for

the rocking motion. A longer connector extended to

a shaft in the shoulder area to which the arms were

fastened. These cams were cut in an undulating pattern

from 1/4 inch fiberboard, probably to avoid excessive

wear or flattening of the steel cam pawl rollers.

Rotating approximately once every eight seconds and

usually running during the entire time the park was

open, these cams wore down rapidly and needed frequent

replacement. When such maintenance was not observed,

the worn cams provided a more subdued level of animation.

At right, Laffing Sal showing mechanisms.

(William

Luca collection)

|

|

|

Coil

springs also played a large role in Sal's movements. 2-inch

diameter springs held the hands to the forearms. Large 5-inch

diameter coils joined the arms at the elbows, and a similar

5-inch spring supported the head. Even her breasts were suspended

by springs to provide a jiggling effect as she laughed. Later

in production, three or four one-inch coil springs were substituted

for the larger head spring.

|